How to learn 5S and implementation of it?

In this article, we will learn what is 5 and how to implement it? This is complete tutorial of 5S including demonstration.

In this article, we will learn what is 5 and how to implement it? This is complete tutorial of 5S including demonstration.

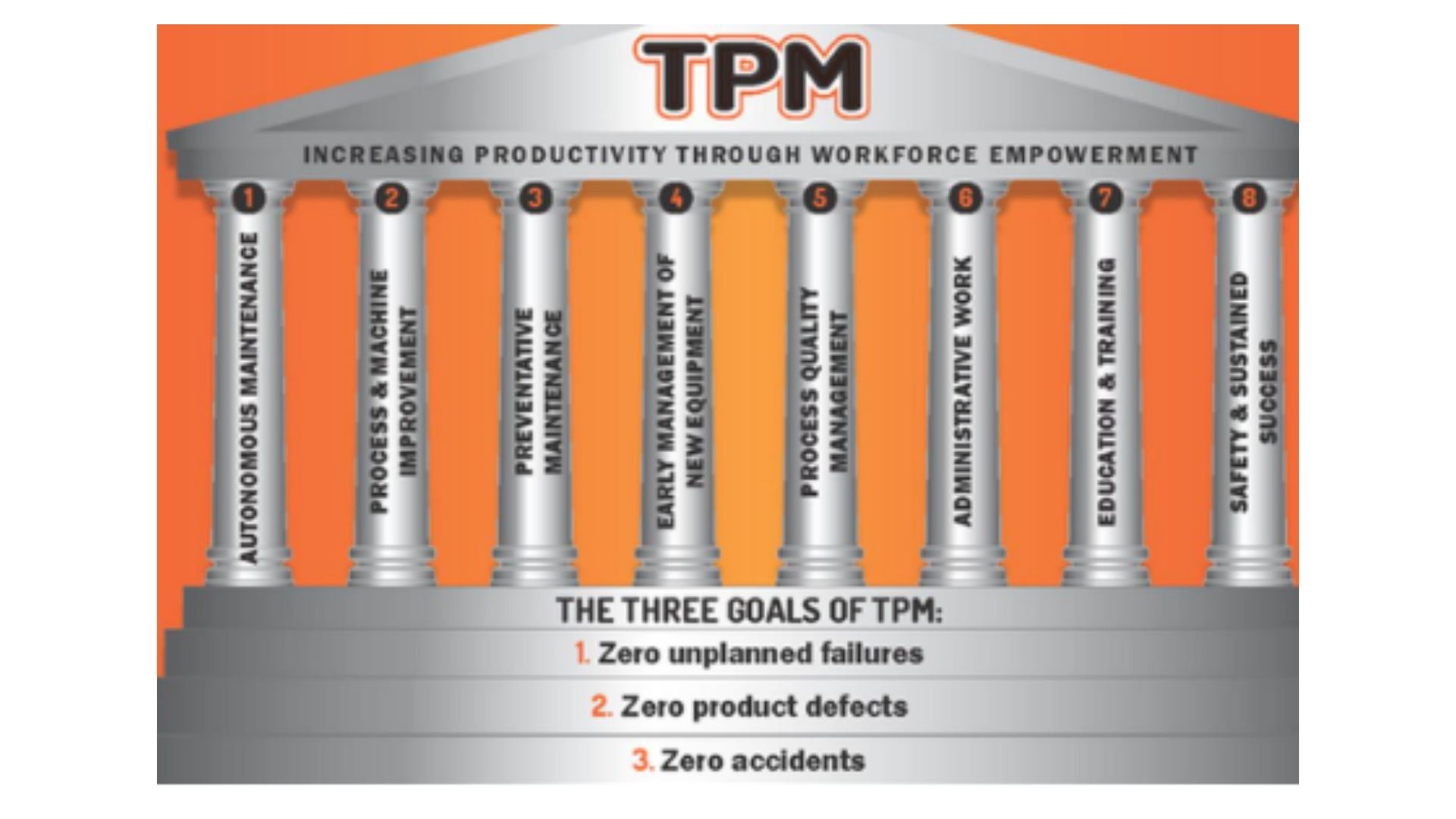

This total productive maintenance checklist is used to assess the progress made toward achieving the company's TPM program goals, starting from autonomous maintenance (AM)

Lean was originally created by Toyota to eliminate wastage and inefficiency in its manufacturing operations. The process has known such success that it has been adopted in the manufacturing sectors of the whole world. Pour une entreprise Americanie, être lean est éssentiale pour compéteur les pays low cost.

The ability to identify and resolve quality-related problems quickly and effectively is essential for anyone working in quality assurance or concerned with process improvement. With the seven basic quality tools in your arsenal, you can easily manage the quality of your product or process, whatever the sector you serve.

TQM emphasizes the importance of understanding and meeting customer needs and expectations. To achieve this, organizations must collect and analyze customer feedback, and use it to improve their products and services.

Learn how businesses can measure and improve the overall equipment effectiveness (OEE) of their production operations to optimize efficiency, reduce downtime, and enhance productivity.